Squeaking and rattling sounds in the Tesla Model 3 and Model Y while driving.

The worldwide Tesla community of the premium electric car reported squeaking noises and rattling in the Model 3 and Model Y. The drivers pinpointed the irritating sounds to the upper front control arm. Some drivers also reported hearing a general rattling sound in the suspension and a decline in steering precision.

And it wasn’t only the Tesla community that pricked up its ears – MEYLE was in the know right away too. Stefan Bachmann, Head of Steering & Suspension, MEYLE AG:

‘We’re connected with car enthusiasts around the world and always have our finger on the pulse of the latest trends and acute issues. Particularly when it comes to poorly conceived technology, we immediately start to look into things. We obviously wanted to get to the bottom of the squeaking sound immediately. Because we are driven by principle.’

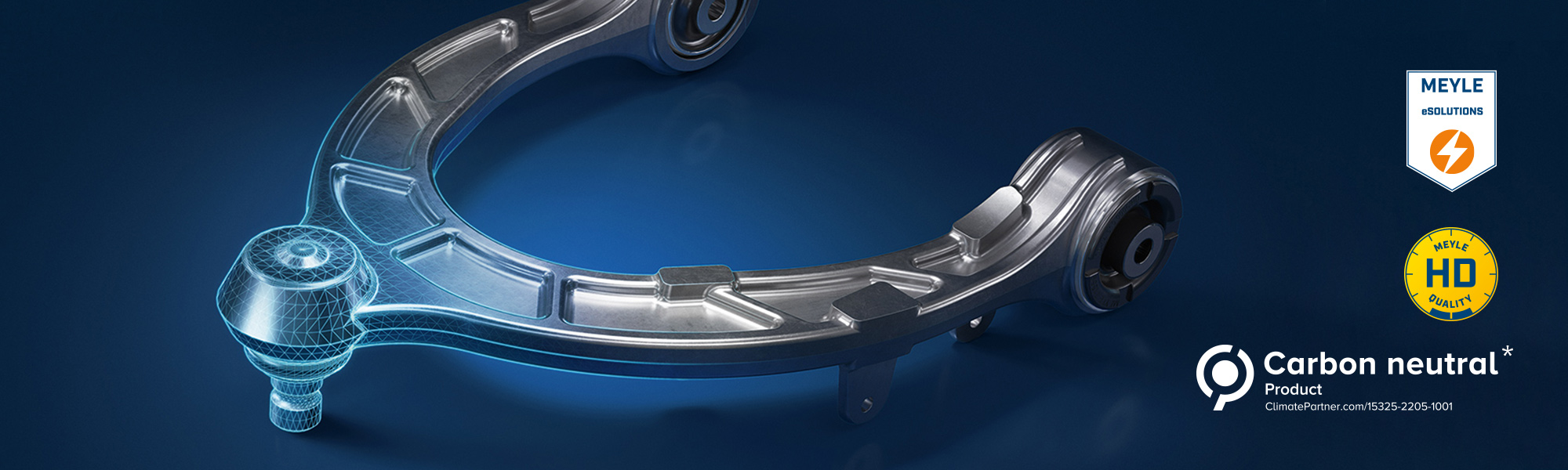

MEYLE no. 70-16 050 0039/HD control arm kit incl. mounting material, 70-16 050 0009/HD left control arm, 70-16 050 0010/HD right control arm.

We take a close look.

The MEYLE AG engineers identify the problem.

After numerous evaluations, the development team determined that the Tesla Model 3 and Model Y control arm does not have sufficient moisture protection. The control arm’s construction makes it a lot easier for water to penetrate the joint. In conjunction with the position of the control arm in the windscreen’s water drainage channel, a significant amount of water can then penetrate, resulting in corrosion of the joint. High performance potential and the Tesla’s high vehicle weight can take a heavy toll on the suspension components, subjecting the control arm to enormous stress and quickly leading to the problem described above. The bushings are likewise subjected to very high wear due to this stress. This all leads to the unwelcome, irritating squeaking sound, damages the ball joint and can potentially result in a loss of driving precision.

The technical improvements to the MEYLE HD control arm for the Tesla Model 3 and Model Y

Following intensive development work, the MEYLE engineers came up with the MEYLE HD control arm for the Tesla Model 3 and Model Y as a technically enhanced solution that lasts significantly longer and boasts extended driving safety and driving fun.

Sturdy control arm body design

The MEYLE HD control arm is made of high-strength, forged aluminium to improve rigidity and consequently also the driving experience. FEM-optimised design for high safety reserves and a low net weight.

Ball joint design

The new ball joint design has no openings or grooves in the upper part. Consequently, water cannot collect there. Additionally, its absolute tightness guarantees that water drains away even when a lot of water is able to enter.

Increased ball head diameter

The diameter of the ball stud has been increased to be better able to absorb the large strains of powerful vehicles. The result is less surface pressure and wear, leading to a longer service life.

Optimised HD bushings

Custom bushings have been developed and manufactured for the specific requirements of the powerful Tesla Model 3 and Model Y, offering a longer service life.

We make it better.

The MEYLE HD principle. The extensive, multistage re-engineering process.

MEYLE HD is the hallmark of high durability and stands for high-quality products that are technically superior to OE parts. The reinforced and optimised design as well as the high-quality materials we use make MEYLE HD parts more durable and reliable. Simply put, they last longer. It’s why we offer a four-year guarantee* on all MEYLE HD parts.

To live up to these high standards, the MEYLE engineers analyse an original equipment manufacturer’s OE parts, find their weaknesses and potential for improvement, and use these findings to develop technically superior parts. These parts are then comprehensively tested in our test centre, after which a prototype is developed before the part finally goes into production. This multistage re-engineering process is the way MEYLE works, ultimately creating a new MEYLE HD part.

And this is precisely how we proceeded in our development of the MEYLE HD control arm for the Tesla Model 3 and Model Y. Because we are driven by principle!

MEYLE AG. A pioneer and driver of the electric mobility turnaround.

Not only does MEYLE have its sights firmly trained on developments in the electric mobility market. Since 2016, we have also been actively promoting the electric mobility turnaround with innovative solutions for the IAM. When developing tomorrow’s spare parts, we draw on our own team of engineers which has unceasingly been looking for innovative ways in which to sustainably improve OE parts for 20 years. Various product teams are currently working hard to expand the portfolio for hybrid electric vehicles (HEV) and battery electric vehicles (BEV).

And they are making a success of this – the product portfolio has already tripled in size over the past three years. MEYLE currently has more than 3,300 products for (hybrid) electric vehicles in its portfolio, more than 1,000 of which are for BEVs, meaning they are all-electric. And this is merely the beginning as we work with our customers to put electric mobility on the road and move it into the future.