We believe that it is also our responsibility to leave future generations with an intact environment and ensure a bright future.

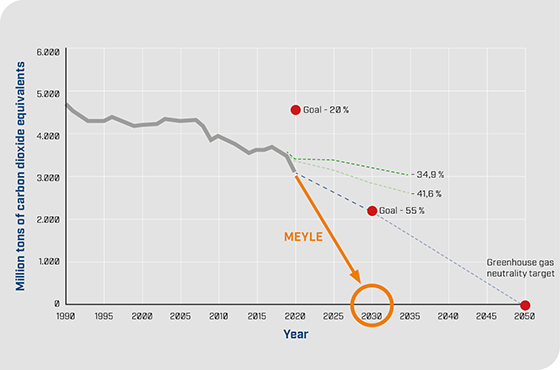

It’s absolutely essential that we set ambitious CO₂ targets in an effort to protect the environment and slow down climate change, which is why we’ve made the decision to ensure that all our products are carbon-neutral by 2030.

We’re developing a sustainable value chain for environmental and climate protection, ranging from product development to dispatch. Our vision is to be ‘the ones with the better and more sustainable automotive parts’.

With our MEYLE HD products, we began developing spare parts that are more durable and more reliable 20 years ago. After all, parts which are more reliable and more durable simply keep vehicles on the road for longer, make repairs and maintenance more efficient and delay the purchase a new car.

Our goal is to design spare parts in such a way that our customers can install, remove and repair them more easily. That they can replace individual components and don't have to throw them away. Because for us, sustainability is first and foremost about answering the central question of how to consume less, consume less.

The MEYLE HD control arm 3 in1 with a 4-year warranty exemplifies our efforts to develop intelligent and truly sustainable solutions for our customers. It orders one spare part and has 3 versions in stock. This conserves resources, saves transport costs and storage space, and results in less waste and CO₂. That is sustainable. That makes sense to us.

And with the first certified climate-neutral MEYLE HD product line in the field of suspension and steering in the IAM, we have taken the next step.

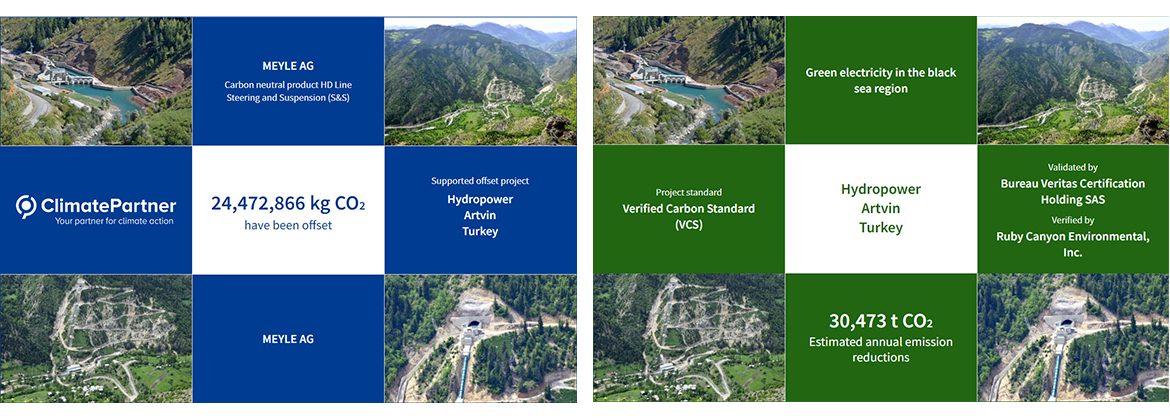

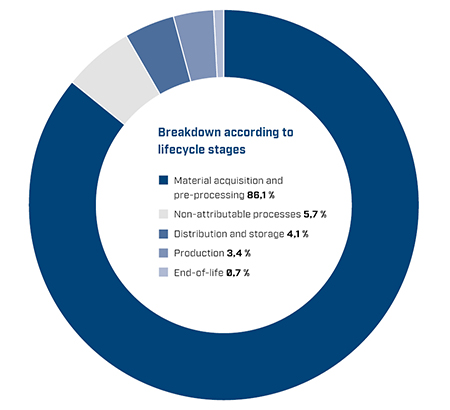

On behalf of MEYLE AG, ClimatePartner has calculated the carbon emissions of the MEYLE HD Steering and Suspension product in accordance with the Greenhouse Gas Protocol Product Life Cycle Accounting and Reporting Standard (GHG Protocol).

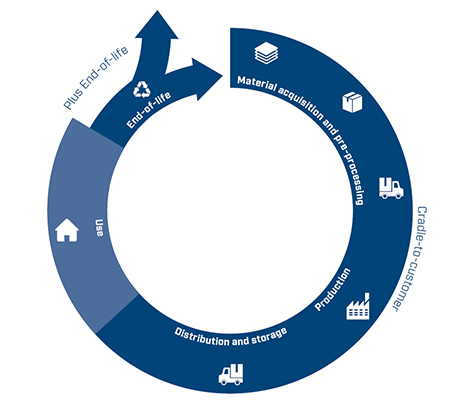

This product carbon footprint was calculated on the basis of the ‘cradle-to-customer plus end-of-life’ approach, taking into account the emissions throughout subsequent life cycle phases: extraction and preparation of raw materials and packaging, production, delivery of the product to the customer’s factory, and relevant emissions associated with disposal of the product and its packaging.

With the ‘cradle-to-customer plus end-of-life’ approach, calculation focuses on the processes controlled by the manufacturer. Because the emissions released during the utilisation phase can rarely be controlled and are subject to assumptions and estimations regarding use, they were not considered in the calculation.

Wherever possible, calculations were based on primary data. Where this was not possible, secondary data from recognised sources were used. The underlying emission factors come from internationally recognised databases such as ecoinvent and GEMIS. All the relevant greenhouse gas emissions were taken into account – however, the calculations were carried out with CO₂ equivalents to improve comparison.

Emissions that cannot be assigned directly to the products, but are necessary for production, such as employee commutes and business trips, were also incorporated into the calculations as general emissions.

Second step: reduction

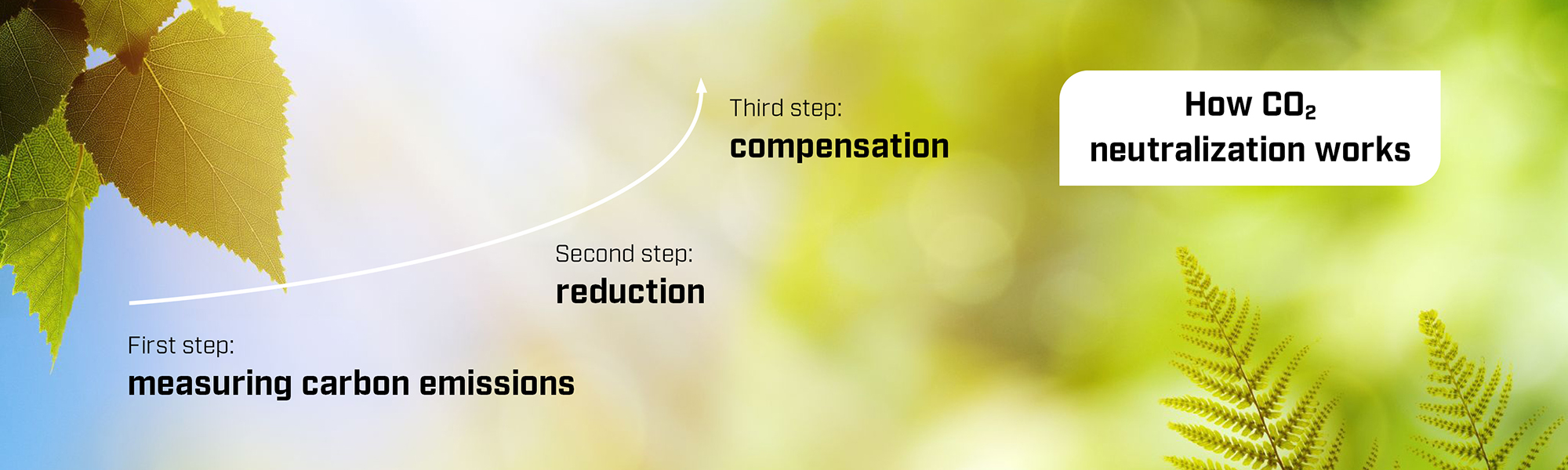

Comprehensive climate protection is based on the principles of extensively preventing emissions, reducing existing emissions and compensating for unavoidable emissions. Calculating the product’s carbon footprint can help identify potential for preventing and reducing emissions and, on this basis, enable compensation for unavoidable emissions. As a result, the product is climate neutral and can be labelled as such.

Preventing and reducing emissions

There are generally two options for preventing and reducing emissions.

- An innovative product design, the associated reduction in materials, improved energy efficiency in production, and regional procurement of raw materials and packaging can prevent emissions even before they occur.

- Making a conscious decision to use low-emission raw materials, packaging, energy sources, and transportation can further reduce product emissions.

Third step: compensation

Carbon reduction measures usually need to be implemented gradually over a longer period of time. Those emissions which cannot be prevented should be compensated for with internationally recognised climate protection projects. It has been proven that climate protection projects can reduce CO₂ – for example, with reforestation or expansion of renewable energies. Independent organisations monitor the exact volume of CO₂ reductions, which are sold in the form of certified emission reductions to finance the project. Further information is available at https://www.climatepartner.com/en/carbon-offset-projects.

The resulting emissions are compensated for, making the MEYLE HD Steering and Suspension product climate-neutral. We therefore assume responsibility from the very start for emissions which cannot yet be prevented.

To ensure that all the resulting emissions within the system limits are compensated for, 10% is added to the overall results as a precaution, thus compensating for any uncertainties related to the underlying data which occur naturally as a result of using database values, assumptions, estimations and other factors.

MEYLE’s first large-scale climate protection project for compensating for CO₂ associated with the MEYLE HD Suspension and Steering products

Green energy in the Black Sea region

The importance of Turkey as an energy market is growing continuously – in terms of both supply and demand. Building new conventional power plants to cover demand would inevitably lead to a major increase in greenhouse gas emissions. But if you want to cover the country’s increasing energy demand in a natural way, you need to invest in the use of renewable energies.

The purpose of the project is therefore to build a new run-of-the-river hydroelectric power plant on the Papart river in Turkey’s Artvin Province. Using the water’s energy and three modern turbines, the power plant feeds around 58.49 gigawatt hours into Turkey’s national grid annually.

A reservoir is not necessary for a run-of-the-river hydroelectric power plant of this size, meaning people who live near the river do not have to relocate and natural habitats and productive arable land remains intact.

How does climate protection work with hydroelectric power?

Hydroelectric power is generated without the use of fossil fuels and is therefore considered to be free of emissions. The production of renewable energies will need to be expanded to curb global warming and secure the energy supply over the long term. The total reduction in emissions associated with a hydroelectricity project is calculated in accordance with the baseline method: How much CO₂ would result from the same amount of energy if it were sourced from the region’s conventional energy mix?